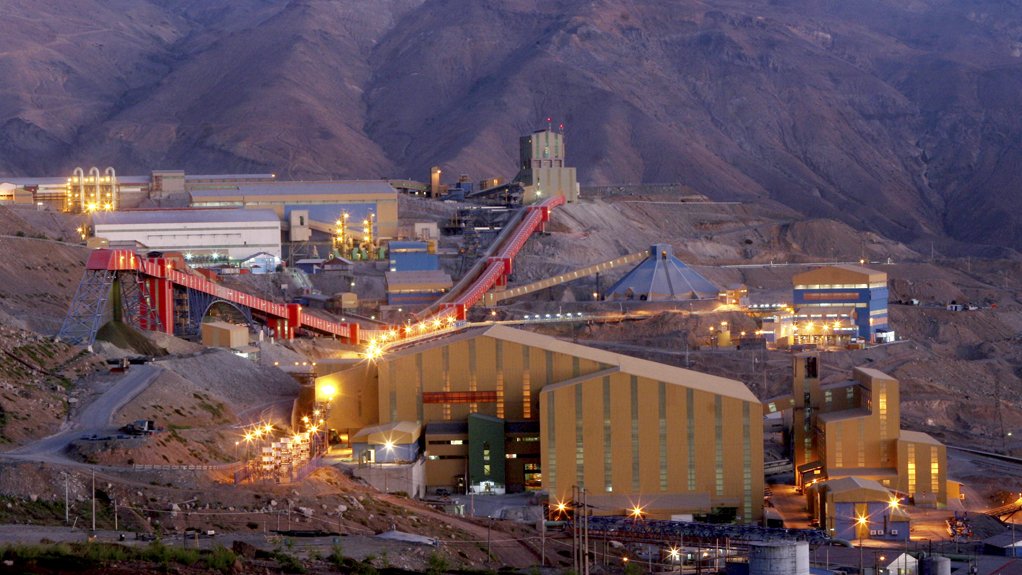

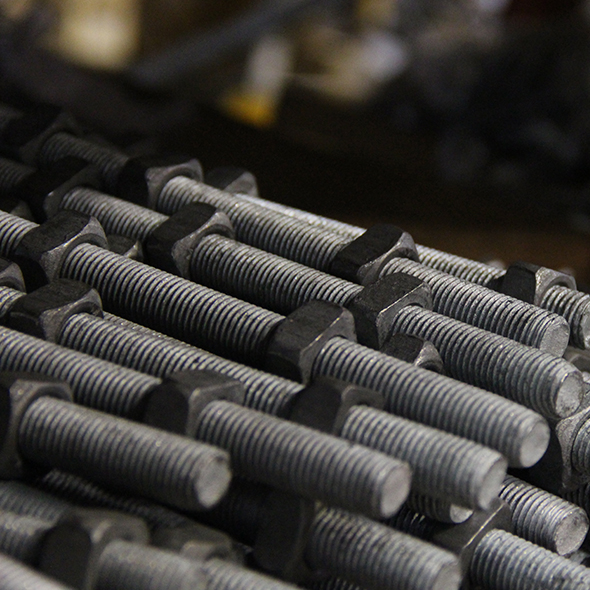

PV Hardware (PVH), a manufacturer of solar racking solutions based in Spain, will provide its trackers for a solar project in Chile with a capacity of 109.76 MW. The firm has been chosen to provide its AxoneDuo Infinity trackers for the Alcones initiative in Chile. The solar initiative also encompasses the construction of a 33/110 kV substation along with a 9KM transmission line. PVH’s trackers aim to enhance solar plant efficiency, offering flexibility for varying terrains and circumstances. Their internal pre-assembly procedure minimizes on-site parts by more than 70%, resulting in a 40% reduction in installation time. The solar farm will produce enough electricity to supply power to over 86,000 households when it becomes operational. In solar farm construction, cross plate anchors fasten structures such as solar trackers to the earth. They provide stability and strength against environmental forces.

Cross plate anchors feature a central rod with steel plates at the base that are arranged perpendicularly, creating a cross formation. This aids in offering improved retention ability when instilled in soil. Employing cross plate anchors in the installation of solar farms enhances the overall reliability and efficiency of the energy production system. This is achieved by keeping solar panels oriented during difficult weather situations. Solar farms require strong bases to sustain photovoltaic panels and solar trackers. The plate anchors additionally guarantee the longevity of solar tracking systems, particularly in extensive solar projects.

Roles of cross plate anchors in Chile’s solar power facility

Cross plate anchors provide stability and longevity for the structures that mount solar panels. The incorporation of cross plate anchors in the development of solar farms in Chile highlights the significance of stability and efficiency for large-scale solar initiatives. This can enhance energy production while guaranteeing lasting reliability and sustainability in Chile’s renewable energy industry. Here are the roles of the cross plate anchors in the solar farm of Chile.

- Structural integrity – cross plate anchors fasten the mounting frameworks into the earth. They offer a solid base and stop the solar panels from moving. They are essential to guarantee the system can endure seismic forces that are susceptible to earthquakes.

- Load distribution – the anchors aid in distributing the weight of the solar panels and mounting systems over the ground. This is crucial in regions with unstable or loose ground to avoid sinking or leaning.

- Resistance to environmental stress – Chile experiences diverse climatic conditions that can expose the solar farm to severe weather events. The cross plate anchor guarantees the system stays stable during strong winds, temperature fluctuations, and various other conditions.

- Corrosion resistance – the anchors are made from galvanized steel or materials that resist corrosion, which is essential in environments with high salinity.

- Simplicity of setup – cross plate anchors provide rapid and effective installation, which is essential for extensive solar initiatives.

- Durability – cross plate anchors enhance the longevity of the solar setup by offering a strong and stable base. This aids in lowering maintenance expenses and guarantees steady energy generation.

Technological advancements adopted by PVH solar farms in Chile

PV Hardware has launched various technological advancements besides trackers in its solar farm projects in Chile. These advancements improve efficiency, flexibility, and sustainability. They assist in advancing the nation’s renewable energy objectives and establishing new benchmarks in solar technology deployment. TTF Power supports the development and construction of solar farms in Chile. This is by providing products like overhead line hardware, transmission hardware, distribution hardware, conductors, insulators, cutout switches, anchoring and grounding products. The upcoming technological advancements aiding solar farm growth in Chile are as follows.

- Solar trackers – PVH’s AxoneDuo Infinity trackers are engineered to enhance energy output by tracing the sun’s trajectory over the course of the day. The trackers provide enhanced flexibility for different terrains and weather conditions. Solar trackers ensure ideal panel positioning and enhance the effectiveness of solar systems.

- In-house pre-assembly procedure – PVH has established a groundbreaking in-house pre-assembly procedure to cut labor on-site. This contributes to reducing the number of required components on-site by more than 70%, resulting in a 40% decrease in installation time.

- Sophisticated control systems – PVH incorporates intelligent controllers and cutting-edge SCADA software into their solar tracking solutions. The technologies ease immediate monitoring and accurate management of the trackers. They also permit adaptive reactions to changes in the environment.

- Change to agrivoltaics – PVH has modified its trackers to ease agrivoltaics applications, acknowledging the increasing trend of merging agriculture with PV systems. This flexibility encourages sustainable land stewardship methods and optimizes land usage.